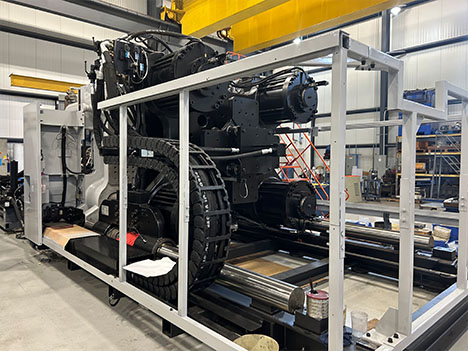

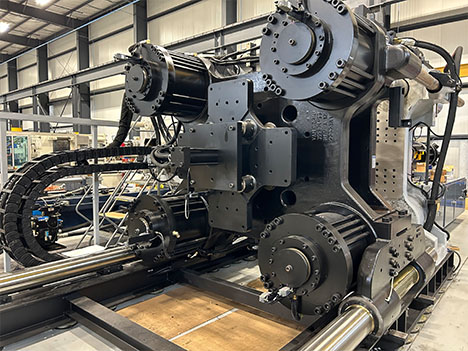

Rebuild in Progress

|

|

|

|

|

Rebuild Includes (but isn’t limited to):

- Clean and paint in OEM colors with new decal package

- Platens cleaned and sanded, all platen holes repaired

- New clamp bushings

- New ejector guide rods and bushings

- Ejector cylinder rebuilt

- New Pneumatic air cylinder and valve

- New/rebuilt traverse cylinder

- New caliber, position cylinders

- Motors rebuilt

- All new pumps

- New heat exchanger

- New robot interface

- Fully rebuilt and tested injection unit

- New heater bands and barrel cover

- New wire harness

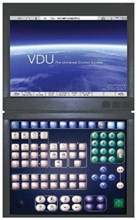

- New VDU2 controller

- When complete, machine will be fully runoff and tested

VDU2 Upgrade Features:

- Closed loop injection control profile with up to 10 steps

- Cut-off selection by time, position or hydraulic pressure

- Closed loop pack and hold profile with up to 5 steps

- Coordinated closed loop recovery with selectable 5-step screw speed and 5-step back pressure profiles

- “Drag-n-Drop” setting of all profiles

- Real-time trace of the entire injection process

- Selectable two-stage low pressure close with try-again circuit

- Programmable auto-purge

- Standard single core system with selectable set, pull and unscrew modes

- 16-channel selectable process monitoring with programmable tolerance alarms, grahpical and tabular display

- Data logging with export to Excel

- Auto-tune barrel temperature control with graphical monitoring

- Production data system with programmable end of production

- Internal and USB mold and calibration setup file storage

- Internal and USB key user access system, USB printing and print-to-graphic file, USB hub with three access ports

- Large 15″ high resolution touch-screen and multi-function keyboard for manual machine functions and system navigation